Out of all the definitions of circular economy out there, our most relatable and dearest definition is by Ellen Macarthur Foundation. It goes to define circular economy as a systems solution framework that tackles global challenges like climate change, biodiversity, waste and pollution.

Circular economy in concept and theory sounds like a very technical and utopian concept which hasn’t found its age. However, what remains surprising is that the term “sustainability” and “circular economy” use in social media has increased over quite the figure. 5000 times to be callously precise. Circular economy is driven by design and todays and tomorrow’s pipeline technology makes it increasingly possible for us to transition into net zero.

Within our system of take-make-waste system, we must transform every element. Right from how we manage resources, how we make and use products and more eminently what we do with these materials afterwards. Every product we end up buying has a life cycle. It has been very difficult for consumers to grasp this concept, however over the last decade more and more waste sites are noticeable and consumers are taking cognizance of it (read: taking responsibility of the share of the guilt).

Whether it is a cans, car, ships, electronics- every products that is manufactured; they can be reused, recycled or disposed of at the end of useful life. Life Cycle Thinking is a term that is quite widely used to explain the integrated thinking that goes into solving today’s sustainable problems.

Whether it is a cans, car, ships, electronics- every products that is manufactured; they can be reused, recycled or disposed of at the end of useful life. Life Cycle Thinking is a term that is quite widely used to explain the integrated thinking that goes into solving today’s sustainable problems.

Which brings us to look at the celebrity of the waste space “Plastic” and how it can learn from the steel economy.

Maersk Line, a very popular shipping and freight line is transforming it’s supply chain policy. Maersk is exploring how to prepare high quality ships for quality designs in it’s initial phase. The shipping industry is currently very much dependent on two commodities. Steel and Fuel. The body of a ship comprises of around 98% of the volume of the ship. There still remains challenges of creating a value ecosystem of strong & resilient vendor and supplier network, but initiatives by leaders go a long way in driving and rallying market sentiments and motivations.

It is key that it is mentioned that recycling steel is comparatively easy to recycle than plastic. That is why, almost 40% of steel around the world is recycled. Steel is sorted using magnets on the other hand, sorting and recycling plastic takes complex processes and scale of investments.

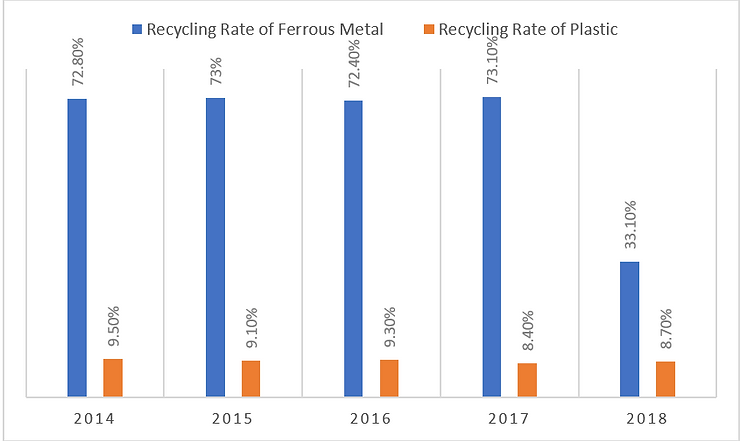

The graph above is a visual representation highlighting the difference in the recycling rate of ferrous metals and plastic. While the recycling rate of ferrous metal hovers around 70% with just 2018 being an anomaly, the recycling rate of plastic remains at 9%. Ferrous metal includes both iron and steel. Owing to the unavailability of data, we had to restrict our analysis between ferrous metal and plastic, in the hopes of extrapolating the comparison between steel and plastic through this.

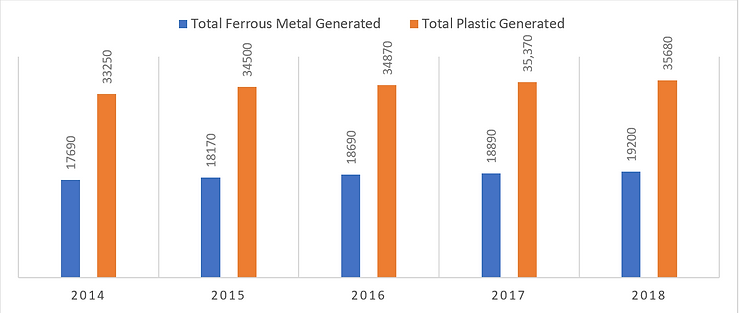

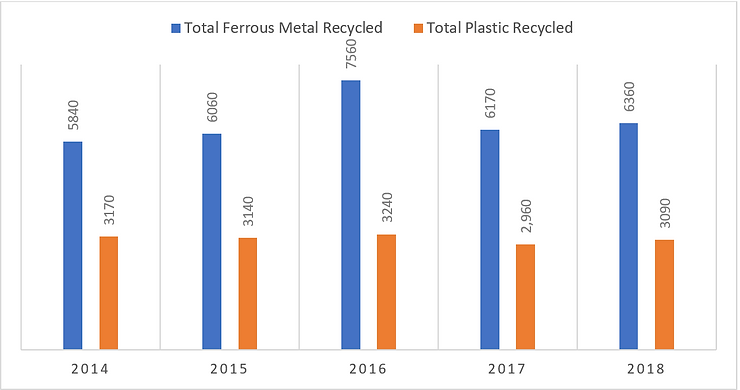

While it is very evident that the recycling rate of Steel is higher than the recycling rate of Plastic, one fair point of contention is the volume of each of the products recycled. This is because the amount of Plastic recycled could be significantly higher than Steel and yet continue to have a smaller recycling proportion than its counterpart. Recycling rate depends on the amount recycled relative to the amount generated, therefore an analysis of the volume of Plastic and Steel produced becomes imperative.

The two graphs posted above showcase the total volumes of Plastic and Ferrous Metals generated and the amount recycled. The upper graph underscores the fact that the volume of Plastic generated is almost twice the number of Ferrous Metals. On the other hand, the volume of Plastic recycled posits to be half the amount of Ferrous Metal recycled.

Even after accounting for the fact that Ferrous Metal includes both Cast Iron and Stainless Steel, the volume of Plastic recycled continues to be lower than Steel. Therefore, it can be asserted with confidence that steel is more recyclable than Plastic.

Why is Steel more recyclable than Plastic?

Steel can be completely recycled without it resulting in a loss of its innate material properties. Recovery rates of steel can range from 50 % to 98% in commercial and industrial buildings, unless it’s the automobile industry wherein steel can be trusted with a 100% recovery rate.

Steel’s promising rate of recovery can be attributed to its magnetic property. Its magnetic property enables steel to be separated from almost any waste stream. While recycling steel requires heavy planning for end-life management, it is highly cost-effective and it cheaper than dumping the waste into any landfill.

As raw materials become more and more scarce, price of steel continues to rise. The interlink between the raw materials and steel ensures that the demand and incentive to recycle steel also continues to increase. Consequently, Steel thrives in the circular economy and is a mile ahead than Plastic in the race of sustainability.