The potential for achieving circularity in the fashion and textile industry, where raw materials are in continuous circulation is extremely achievable. However the barriers remain challenging.

Let’s Rethink the Global Textile System- And it starts with clothing.

Textiles and clothing go hand in hand of our everyday life and encompasses an important vertical of the global economy. To draw some perspective, globally the clothing industry employs more than 300 million people along the value chain. The production of cotton accounts for more than 7% of the global value chain.

The current system operates on a pretty linear way where clothes are produced, distributed and used. There is a consumption of a large amount of natural resources which are used to in the entire life cycle of the clothes which are really short as well. This leaves a massive economical gap.

Consumers in today’s age are more aware of sustainability and it being an increasing driver in making purchasing decisions. As social media and news outlet dominate the online space, shining required light on social and environmental responsibility in the fashion industry. The mention of the word “sustainability” stands at all time high since 2015. The level of integration of awareness is highest among millennial category.

This remains a celebrated ray of optimism, however the reality remains that consumer considerations of sustainable factors do not remain the top priority while making purchasing decisions. Aesthetics and quality still does. Even though 7% of consumers have this as their considerations, it would be unjust to equate that only consumer movement will drive adoption of ethical and healthy practices in the fashion industry. There remains a commanding need for the fashion leaders to take stronger lead in making this transition.

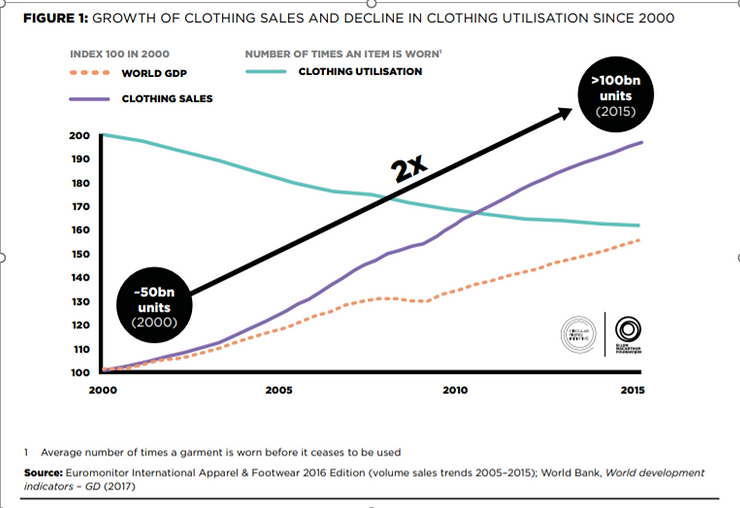

One other grave tangent of the waste and fashion industry is a new evolving trend. The average number of times a garment is being worn has dramatically gone down. There is a global decrease of around 35% of the life cycle of a garment compared to 15 years ago. Fast fashion is one of the gradual reasons for this trend. Since 2017 there has been an uplifting trend of sharing dresses model where, innovative business models were promoting strong reception of the idea that a garment can be “passed on” and therefore increase it’s life cycle. With the post covid atmosphere, it seems rather difficult for it showing any possible revival in the near future with reports showing that consumers are more and more being concerned of their personal hygiene. It is estimated that globally, consumers miss out on close to USD 421 Billion by throwing away clothes they could have continued to wear.

Source: Ellen MacArthur Foundation

It is estimated that almost 73% of the material going into the clothing system looses it’s value after final garment use. 10% of it is lost during garment offcuts and production and the remaining 2% is sent to landfills or incineration centers. There is an additional 2% loss that occurs in the collection and sorting of discarded clothing. Slightly less than 1% of material that is used to produce clothing is recycled into new garments or clothing products.

Our understanding remains that less than 0.1 % of the garments that are used find their place in the textile/garment/fabric waste recycling value chain. And this remains an extremely sorrow affair. Only 13% of the total material inputs in some way or the other are recycled after clothing use. The majority of these items are lower value applications such as wiping cloths, insulation materials and mattress stuffing’s.

The New Textile Economy- The Profitable Green

The basic theme of the new textile economy encompasses the principles that govern the circular economy, one that is regenerative however also remains profitable and acceptable among consumers therefore motivating business to innovate better and faster to align themselves.

A new textile economy provides and produces access to affordable and high quality products. Under this model, everyone has access to clothes when they need them. The belief is that new business models will allow more flexibility on which clothes to wear therefore giving rise to personalized and controlled production.

This is where it is also important to point out that under this model, clothes are used more often, therefore allowing their value to be captured radically. Once clothes have reached their end of life cycle, they can be re-generated. That can be done by ensuring that there is no contaminating element used in the production of clothes that devalues the materials therefore ensuring recyclability is possible

This model will also strongly advocate the use of renewable energy for production of clothes and garments. The energy required to fuel new textiles economy is renewable by nature, therefore decreasing resource dependency and increasing system resilience. The inputs need to be regulated and standardized. Also the price of the clothing should be a reflection of the entire cost of production which includes environmental and societal externalities.

Lastly and severely, as an integral part of promoting overall healthy system, a new textile economy presents new opportunities for distributed and inclusive growth. It creates a thriving ecosystem of enterprises from large to small retaining the core value of circularity.

Moving to Joint investments and Long Term Collaboration between retailers and manufacturers.

Brands that are working together with suppliers to implement processes improvements will eventually build trust and better transparency. To take an example Nike’s Rewire approach is a long term supply chain strategy based on integration and incentives. One of the crucial aim of the program is to become more efficient and innovative. In order to measure progress, Nike has introduced the manufacturing index across its supply chain. Factories that are contracted under Nike are measured and incentivized on their sustainability practices. Nike also organizes training programs for it’s suppliers to optimize resource, energy, health and safety. This model forces supplier to aim for the highest standard of practice instead of just following it.